Syringe Filters: A Guide to Selection, Construction, and Proper Use

Syringe Filters: A Guide to Selection, Construction, and Proper Use

Syringe filters are indispensable tools in laboratories, ensuring that liquid samples are free from particulates, microorganisms, and other contaminants before analysis. Used across industries—from pharmaceuticals to environmental testing—these small but critical syringe filters help maintain sample integrity. However, choosing the right filter and using it correctly is key to achieving reliable results.

What Are Syringe Filters?

Syringe filters are single-use, membrane-based filtration devices that attach to a syringe. They purify samples by removing unwanted particles, ensuring compatibility with analytical instruments such as HPLC, GC, and spectrophotometers.

Common applications include:

⇔ Sterilizing buffers and cell culture media

⇔ Clarifying samples for chromatography

⇔ Removing particulates from solvents

⇔ Preparing samples for microbiological analysis

Key Components of Syringe Filters

syringe filters construction

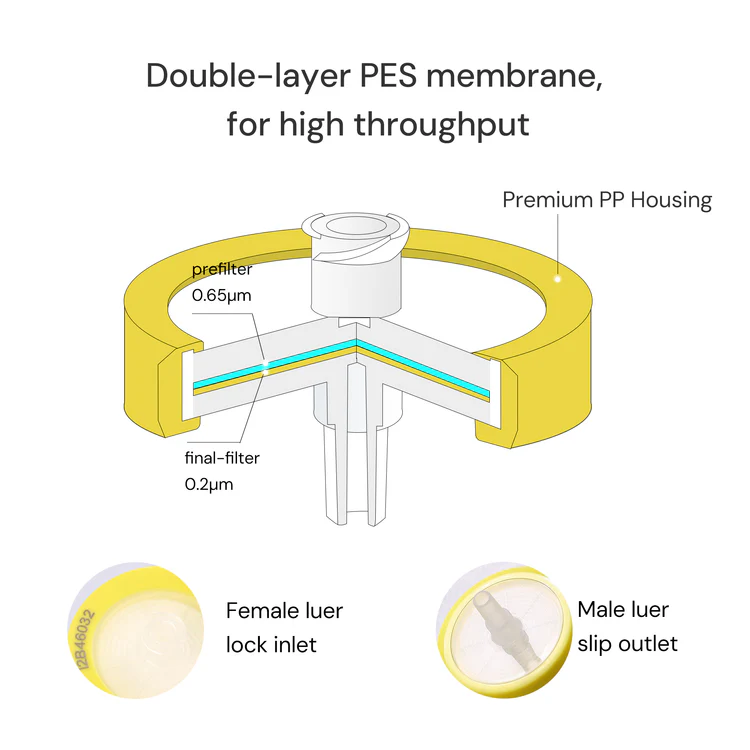

Syringe filters consist of three primary parts:

1. Filtration Membrane – The core component that traps particles based on pore size.

Common materials:

Nylon – Balanced chemical compatibility, ideal for general use.

Polyether sulfone (PES) – High flow rates, low protein binding.

Polytetrafluoroethylene (PTFE) – Hydrophobic, best for organic solvents. Polyvinylidene fluoride (PVDF) – Low extractables, suitable for sensitive assays.

2. Support Layer – A reinforcing mesh or pre-filter that prevents membrane collapse under pressure.

3. Housing – Typically made of polypropylene, designed to securely attach to syringes.

Selecting the Right Syringe Filter

Choosing an appropriate filter depends on several factors:

1. Pore Size

0.1 µm – Removes mycoplasma and very fine particles.

0.22 µm – Standard for sterilization (removes bacteria).

0.45 µm – General particulate removal (not sterile).

2. Membrane Material

Aqueous solutions → PES or Nylon

Aggressive solvents → PTFE

Protein or sensitive samples → PVDF or PES (low binding)

3. Diameter

13 mm – Small volumes (< 10 mL)

25 mm – Larger volumes, reduced clogging risk

4. Sterility Requirements

Pre-sterilized (gamma-irradiated) filters are essential for cell culture and microbiology.

Why Syringe Filters Should Not Be Reused

Syringe filter usage

Syringe filters are designed for single use due to:

✔Contamination Risk – Residual sample carryover can skew results.

✔ Membrane Degradation – Repeated use weakens the filter, increasing failure risk.

✔ Clogging – Accumulated particles reduce flow rates and efficiency.

✔ Sterility Concerns – Reusing a sterile filter compromises its effectiveness.

Common Mistakes in Syringe Filter Operation

To ensure optimal performance, avoid these errors:

❌ Applying Excessive Pressure – Can rupture the membrane.

❌ Using the Wrong Pore Size – May fail to sterilize or clarify effectively.

❌ Mismatching Solvent and Membrane – PTFE filters require pre-wetting for aqueous solutions.

❌ Reusing Filters – Leads to contamination and unreliable data.

❌ Ignoring Pre-Filtration – Highly turbid samples should be pre-filtered to prevent clogging.

Final Thoughts

Proper selection and handling of syringe filters are crucial for accurate lab results. Always match the filter to your sample type, avoid reuse, and follow best practices to maintain efficiency.